Products

Brake System Parts

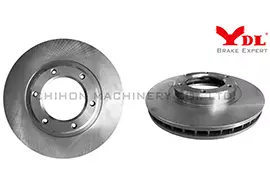

High-Performance Brake System Prodcut for OEM & Aftermarket Applications

Our precision-engineered brake disc rotors are designed to meet the rigorous demands of OEM and aftermarket customers. Whether you are looking for custom brake solutions or high-performance brake components, our products ensure superior performance and a longer lifespan. We specialize in customized brake solutions, optimized for performance and durability, without compromising on structural integrity.

Key Features

Material Excellence

Manufactured from FC250 Cast Iron (Grade 250 / GG25), our brake components deliver exceptional strength, durability, and heat dissipation, making them ideal for both standard and custom applications.

Customized Design for Enhanced Performance

We specialize in designing custom solutions for unique vehicle types, including construction vehicles, waste management trucks, water trucks, and other specialized fleets. All design adjustments are made to optimize performance and extend service life without compromising structural integrity.

Precision Engineering

Advanced CNC machining, precise balancing, and controlled surface finishing are applied to ensure each component meets OEM specifications and exceeds stringent safety standards.

Precision Machining & Balancing

Our commitment to precision starts with state-of-the-art machining technologies and continues through every step of the production process. Each component undergoes rigorous dimensional measurement to ensure perfect fit and performance.

In addition to precision machining, every part is carefully inspected for surface defects such as sand holes, air pockets, cracks, or other non-conformities. Advanced balancing techniques are applied to ensure stable braking performance and long-term durability.

Comprehensive Final Inspections

Before shipment, all products undergo strict final inspections to ensure compliance with our quality standards, including:

- Dimensional accuracy to meet exact specifications

- Stress testing under simulated real-world conditions

- Surface inspection to eliminate defects such as sand holes, air pockets, or cracks

This inspection process minimizes defects and ensures consistent quality across all production batches.

Customized Design for Aftermarket & Special Applications

Our customization approach focuses on performance optimization while maintaining original structural strength. By carefully adjusting design parameters, we enhance braking performance and extend product service life, avoiding risks caused by excessive material removal or improper modification.

Optional Features / Value-added Options

Optional Surface Treatment – ED Coating

ED coating is available as an optional surface treatment to enhance corrosion resistance and improve appearance during storage and transportation.

This option does not alter the structural design of the brake disc and is applied based on customer requirements.

Brake Parts Categories

Our brake components are divided into the following categories:

1. Disc Brake Rotors & Drums

- Automobiles

- Light Trucks

- Heavy Duty Vehicles

- ATV / Beach Cars

2. Brake Pads

- Semi-metallic

- Ceramic

- NAO (Non-Asbestos Organic)

- High Carbon

3. Hose Lines

Custom brake hose solutions designed for reliable performance.

Performance Racing Parts

YDL also provides customized performance racing parts, including brake pads and hose lines. Over the past 9 years, extensive real-vehicle testing has been conducted, including temperature testing and stopping distance evaluation.

Our goal is to identify the most suitable friction materials for fast bedding-in, enhanced braking force, and stable high-performance operation.

Product Applications for Global Markets

YDL brake rotors and drums support thousands of vehicle applications worldwide and are commonly used in:

- Japanese vehicles

- European vehicles

- Korean vehicles

- American vehicles

Solutions are available for passenger vehicles, light trucks, and heavy-duty applications.

Customer’s Samples Welcome

If a required model is not listed, customer samples are welcome. We provide customized development and matching solutions based on actual samples and specifications.

For more details, please visit our product pages or contact us directly.

Application & Vehicle Coverage

- OEM integration for passenger vehicles

- Customized solutions for commercial trucks

- Specialized vehicles, including:

- Construction equipment

- Waste management vehicles

- Water trucks and road sweepers

Why Choose Us

- Reliable & Customizable — Tailored solutions for diverse market needs

- Durability You Can Trust — Designed for long-term performance

- Global Expertise — Trusted by customers in over 31 countries

Request a Quote Today

Whether you are looking for customized brake components or a reliable manufacturing partner, we are here to help. Contact us for a personalized quote based on your vehicle specifications.